From the Workshop

The idea of building a new Whirlwind goes back to the 1980's at least. There were even a couple of attempts to get a build project going but the problem always came back to 'what exactly are we building' as there were so few drawings that survived a flood at Westland's aerodrome in the 60's.

When it came up again on a well known historic aviation forum in 2011, there was a chorus of 'been there, done that, best forget it'.

...If this person reads this - yes please, we would still like that junk.

Only one stubborn voice remained - Mike Eastman of the Aircraft Restoration Group not only said it could be done, he even offered to start doing it.

The Late Stuart Hawkins joined in - he had been working on the rendering of a Whirlwind for a popular flight sim, and as a car bodywork repairer felt a good metal facsimile was easily achievable. Other voices entered the fray - Matt Bearman, Matt Painter, even The late Dave Gibbins OBE, formerly a flight test engineer at Westland and now the archivist for the company. It was his offer of access to whatever Westland still had that kicked off the Whirlwind Fighter Project as something real.

The aim was to work in sections, raising money for each one individually, before embarking on the next, so that we always had cost control and full visibility, avoiding the issues that have beset similar projects in the past.

Mike was as good as his word and immediately started manufacturing parts - for the rear fuselage. By 2015 we had enough to put together a rear fuselage skeleton for proud display at Westlands 'W100' centenary celebrations at the Yeovil factory airfield. Meanwhile Chris Hayward took on the onerous task of organising the scattered group into a membership organisation, complete with a committee, trustees, charitable status and regular meetings plus AGM.

When it came to skinning the frame it was clear that we would need some specialist kit and some real experts in stressed-skin construction. The obvious course of action was to ask Steve Vizard, a friend of the project and owner of Airframe Assemblies, a leading constructor of flying restored WWII aircraft.

Steve had recently invested in a roller press that was perfect for the job - the reason being it was purchased from the Westland factory at Yeovil, who took it on in 1941. It had been used to make Whirlwinds before!

It was around this time that Pete Smith came on board. He had kept behind some plant from his time as a precision engineer, which was capable of turning Gunnar Olsen's data - and some from Matt Painter - into newly manufactured components.

Two years later, we had a complete cockpit section and were embarking on assembly of the manufactured rear fuselage components, joined by the crucial frame 10 first fabricated by Airframe Assemblies.

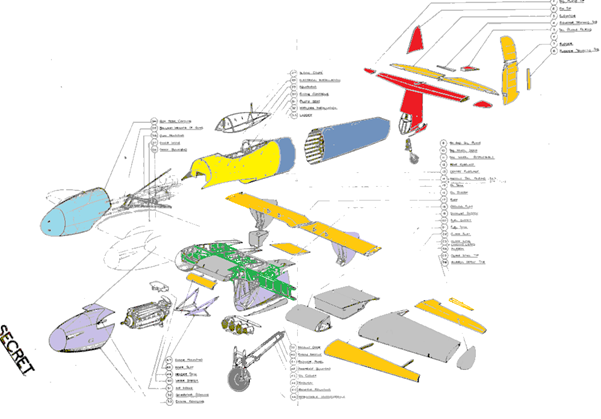

The image below is from a 1940 document in the Westland Archive, and it shows how 'modular' the build can be. After the fuselage and cockpit, blue and yellow, we will then look to create the tail (red) and centre section with spars (green).

With the offer by Dave Brocklehurst MBE of a permanent indoor home as an exhibit at the Kent Battle of Britain museum, Hawkinge, the future of P7056 will be assured once she is complete.